PRODUCT INFORMATION

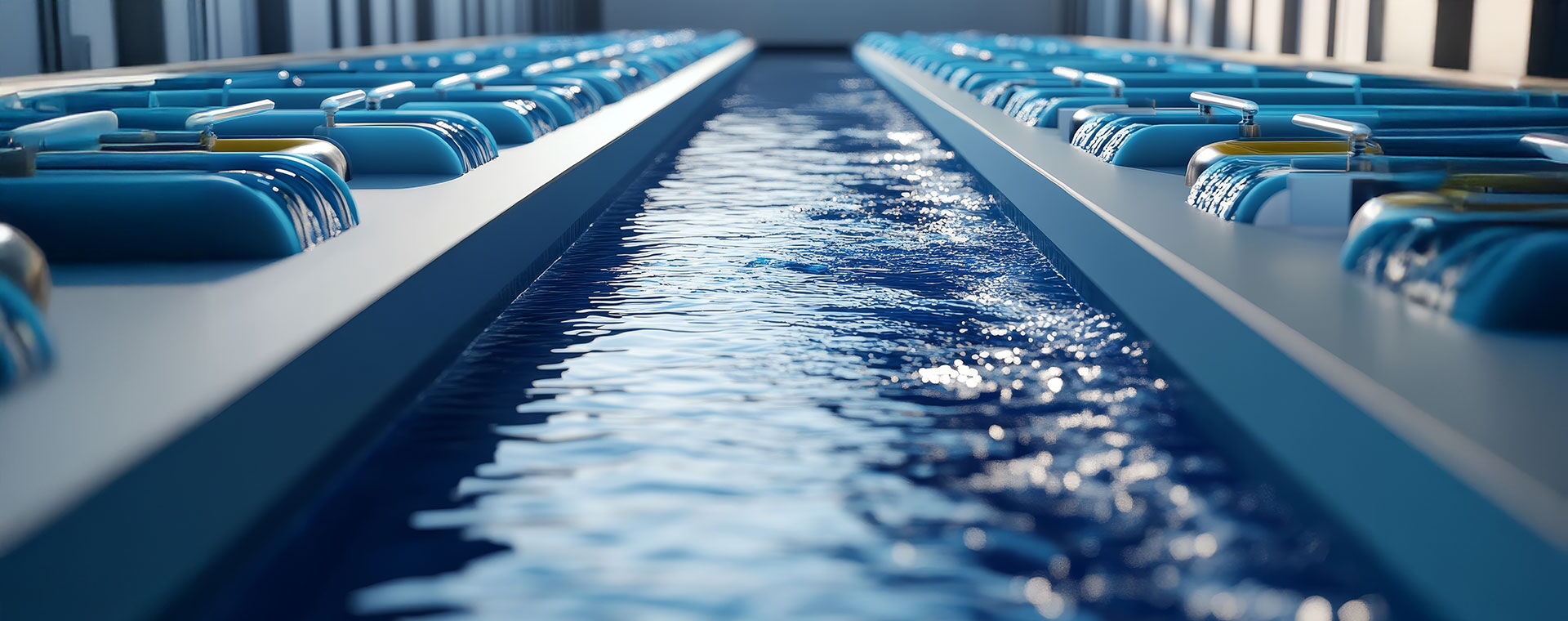

Providing drinking water to meet the needs of the population and industry requires new solutions in view of limited resources, rising costs for drinking water and wastewater treatment plants and stricter environmental regulations. ARTAŞ offers the Package Membrane Bioreactor System (ArMBR®) as a permanent, sustainable solution.

The ArMBR® system is a continuous mud-to-water separation system using membranes that uses flat plate or hollow fiber membrane modules and can be installed either in the aeration basin or in a separate downstream membrane reactor. The MBR modules are often completely submerged in the aeration tank and require soil aeration. The effluent values achieved with ArMBR® are extremely low and the membranes have a disinfecting effect because bacteria are retained on them. Unlike conventional aeration tanks, there is no backflow of sludge in the ArMBR® plant

Applications

Wastewater treatment plants that benefit from the application of a membrane bioreactor (MBR) process are typically those that have high wastewater quality requirements or have to overcome special challenges. Here are some examples:

- Hospitals: MBR technology is often used in hospital wastewater treatment plants to purify wastewater of trace substances and drug residues1.

- Industrial applications: Especially in the food, textile and metal finishing industries, where high concentrations of organic matter and solids are present in wastewater2.

- Municipal wastewater treatment plants: Cities and municipalities use MBR technology to ensure high wastewater quality and meet regulatory requirements3.

- Hotels, holiday homes and resorts, nature reserves: these facilities benefit from the compact design and high efficiency of the MBR systems to save space while ensuring high water quality.

MBR systems offer advantages such as 100% biomass retention, suspended solids-free and low-germ drainage as well as extensive

Scope of armbr® system equipment

- Fine screens

- Anaerobic tank

- Denitrification tank

- Nitrification tank

- MBR Tank

- Mud pool

- Dosage Unit

Advantages of the arMBR® system

- High purification performance with a wastewater value of 5 mg/L BOD, 2 mg/L TSS, 10 mg/L total nitrogen

- Removal of pathogens and coliforms

- Advanced nitrogen and phosphorus removal

- Disinfected wastewater

- Can handle high and variable pollution loads easily

- Equipment is delivered pre-assembled

- Compact design for easy handling

- Easy installation with a small footprint

- Modular, expandable

- User-friendly with flexible process options

- No odor problem

- Enables excellent sludge removal, very low sludge production

- Production tests carried out, fast commissioning

- Simple and reliable operation

- Fully automatic, minimal operator effort required

- 2-year warranty against production defects

- Manufactured according to WHG, ISO 9001, ISO 14001 and OHSAS 18001 standards

- Professional after-sales service

Removal rates of the arMBR® plant

| Parameter | Removal rate |

| BSB (BOD) | > 99% |

| Waste Materials (TSS) | > 99% |

| Kjeldahl Nitrogen (TKN) | > 96% |

| NH3 | > 97% |

| Total phosphorus | > 97% |

| Turbidity | > 99% |

| Faecal coliforms | 6 Log ablation |

Working principle of the armbr® system

Biological systems are processes designed to remove dissolved and suspended solids from wastewater. In conventional wastewater treatment systems, suspended solids are